Publications

We keep important events for you to read in our archive.

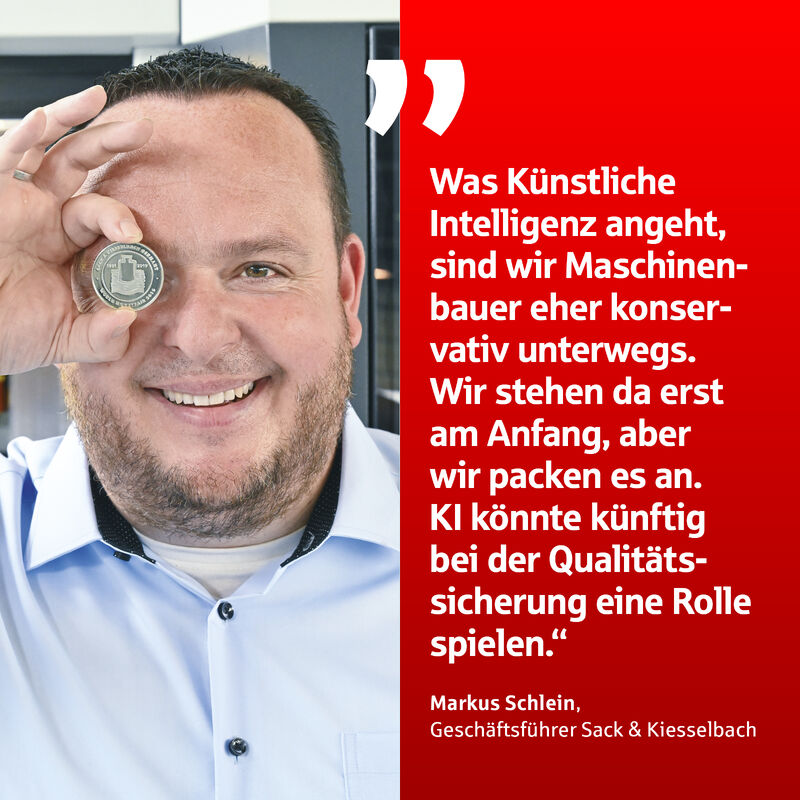

Interview in “Wirtschaftsforum”: Precision in Perfection

In conversation with Wirtschaftsforum, Markus Schlein, Managing Director of the globally operating special machinery manufacturer Sack & Kiesselbach, provides insight into the company’s success factors: With over 100 years of tradition, the machine manufacturing company has made a name for itself internationally with its presses for precious metal coins, medals, and bars. Nearly all major mints use the high-precision systems from Meerbusch – not for circulation, but for high-quality collectibles and prestigious strikes such as Olympic medals. Schlein emphasizes that quality demands in the collector market are constantly rising, and Sack & Kiesselbach meets this trend with innovative solutions – including automated production lines that manufacture up to 20 pieces per minute in the highest minting quality.

In addition to numismatics, medical technology also plays a central role: implants and tools for tablet production are made on the company’s presses, where precision in the micrometer range is required. Sack & Kiesselbach continuously invests in future technologies such as robotics and RFID and relies on a high degree of personal responsibility and co-creation within the team. The corporate culture, characterized by the “Family Spirit,” enables short decision-making paths and customized customer solutions – from individual parts to complete production lines. Around 2,000 machines in operation worldwide, some for several decades, attest to the company’s longevity and innovative strength. Even after more than a century, Sack & Kiesselbach remains an agile technology leader in specialized markets.

Sack & Kiesselbach at the World Money Fair

Markus Schlein, Managing Director of Sack & Kiesselbach, reports on his experiences at the World Money Fair.

Read his article in the Münzwoche.

Sparkasse

Without oil-hydraulic presses, there would be no Vienna Philharmonic. What?! 🤔

That’s right, but of course we’re not talking about the orchestra 🎻, but about one of the world’s most famous collector coins.

Sack & Kiesselbach Maschinenfabrik GmbH manufactures the press systems used to mint these gold and silver coins. Despite the enormous forces at work, the machines operate with great sensitivity. Add to this some “secret ingredients”: experience, know-how, and passion.

Because the company’s 125-year history is set to continue ✒, Managing Director and passionate tinkerer Markus Schlein has been driving the development of new press systems and the automation of work processes in recent years.

To optimize production and maintenance processes, Virtual and Augmented Reality 🥽 are also being used. Markus Schlein has proven that it is possible to produce high-quality coins with artisanal precision work while simultaneously tripling production.

Incidentally, Sack & Kiesselbach currently generates two-thirds of its revenue abroad. Stadtsparkasse supports the company as a well-connected partner in this regard.

Mint Industry Communiqué

Feature: The industry suppliers – Sack & Kiesselbach

Edition May 2021

Mint News Quarterly – June 2020

Digitization made easy – remote maintenance and training by Sack & Kiesselbach

Article by Currency Publications Ltd / Dr. Ursula Kampmann – Edition June 2020

Grace wedding commemorative coins

The London Tower Mint produced commemorative sovereigns on the occasion of the Platinum wedding of the British Royal Couple with their brand-new TMP-350 from Sack & Kiesselbach. The designs were made by Raphael Maklouf owner of the Tower Mint and known to the numismatic world as creator of the third portrait of Queen Elizabeth circulating between 1985 and 1997.

Mint News Quarterly – September 2017

Fast Forward Technology -The first TMA starts work at the Mint in Poland

Article by Currency Publications Ltd / Fr. Dr. Ursula Kampmann – Edition April 2017

Coins Revue – November 2016

International coin trend journal – Network of passion

Article by Herrn A.-M. Beck – Founder and Honorary President World Money Fair

IHK Magazine November 2016

Brand Niederrhein – machines for European champion medals

The Sack & Kiesselbach Maschinenfabrik GmbH in Meerbusch builds press systems.

Fast-Forward Technology put to the Endurance Test

S&K Newsletter September 2017 / TMA-350

The Royal Mint manufactures jewelry, while people become cashless.

Whether the trend really is towards “cashless” is something which many specialist has been arguing about for years.

The Minting Industry itself always discussed this topic! And already after the introduction of the credit card many prognosticated a slow end of the cash money. But even after that, worldwide coin production continued to rise.

Sack & Kiesselbach is not engaged in the production of circulation coins anyway, but serves the market of precious metals, medals and jewellery production with tailor-made and turnkey solutions.

A BBC report currently illustrates a possible trend or change in the market using the example of the Royal Mint in England. Ten TMP presses are currently in operation at the Mint in Llantrisant, helping our customer to compete as one of the world’s leading Mint.

Gold for Germany! Sack & Kiesselbach is involved.

Krakow, 31 January: Germany is the European handball champion. We congratulate them and are proud – of ourselves. Because we too played our part in the triumph. The medals for the European handball championship were minted on a Sack & Kiesselbach press. In world champion quality of course.

The renowned Mint of Polen was responsible for manufacturing them. The medals are 88 mm in diameter and weigh 250 g. The basic material consists of brass (tombak) and were plated with 24 carat gold or coated with 999 sterling silver for the different versions.

The Artur Gosiewski design stands for dynamics, team spirit and a challenge. We think that this also applies to Sack & Kiesselbach.

The medals of the Handball-EM 2016 were made on a Sack & Kiesselbach press.