Control over quality and costs

The State Mint in Berlin produces bimetal/bicolour collector coins in one single processing step on a TMP by Sack & Kiesselbach.

Coins intended for circulation in collection quality

Coins intended for circulation in collection quality are part of the standard programme of the State Mint in Berlin. When it came to the production of euro coins, the question was: pre-assembled bimetal blanks or assembly and minting in one single processing step? The decision was clear.

Assembly and minting in one single processing step has advantages across the board:

- Economic use of the equipment

All processing steps are carried out in one step on one machine. No additional press is used for assembly. - Longer operational life of the die

The softer the blank, the lower the wear and the related costs. Unassembled blanks have a core hardness of about 86 HV30 compared to about 114 HV30 in case of pre-assembled blanks. - Better coin image

The softer the material, the better the flow properties in the coining die. Plus, there is less force required. - Perfect blanks

Separate polishing of ring and core is better and easier technically than polishing pre-assembled blanks. Without a separate pre-assembly process, the risk of resulting impurities or damage is also removed. The blanks remain flawless.

„Changing to assembly and minting in one single processing step resulted not only in more economic efficiency but also led to an improvement in product quality.“

Jürgen Stolz, Managing Director, State Mint Berlin

A perfect minting result requires the most precise feeding and an optimal tool system

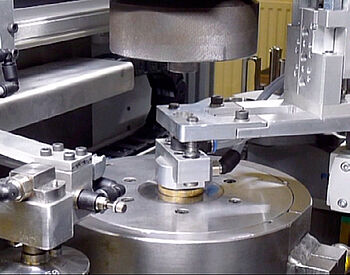

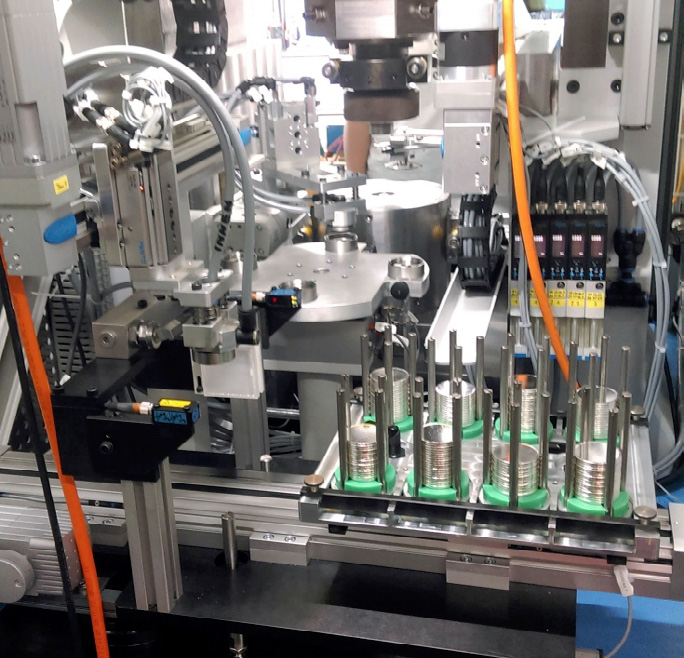

For this task, the table medal press (TMP) by Sack & Kiesselbach was equipped with a special transfer system for bimetal coins.

The automated material feeding is the key to the successful assembly and minting in one single processing step. Ring and core are fed-in separately and precisely placed one into the other by vacuum grippers. This task is far from trivial. For example, based on its weight the ring offers only a small suction surface and requires a high degree of reliability of the system.

Magazineinheit (z. B. für Rund/Mehreck) für Standardmünzen auf dem Bimetall-Transfer-System.

other technology topics

The Birth of the Precious Metal Record

Precious Sound” marks the creation of playable records made from pure gold – a masterpiece of sound, design, and precision. This is made possible by the Downstroking medal press (OMP) from Sack & Kiesselbach, which embosses ultra-fine grooves into precious metals. Mechanical engineering meets music – crafted for eternity.

VR and AR as building blocks of production - optimized thanks to assisted reality

The indispensable building blocks of every production at Sack & Kiesselbach are VR and AR.

Find out everything else about Assisted Reality as an optimal complement to production here.

New dimensions of minting

The small Pacific island state of Niue is known among numismatists as publisher of unusual coin creations. The current “coin” is shaped like a sphere and shows a historical map indicating the seven new wonders of the world with crystals.

The renowned Mint of Poland undertook the realisation of this demanding project.