Setting Standards

Virtual- / Augmented-Reality & assisted Reality

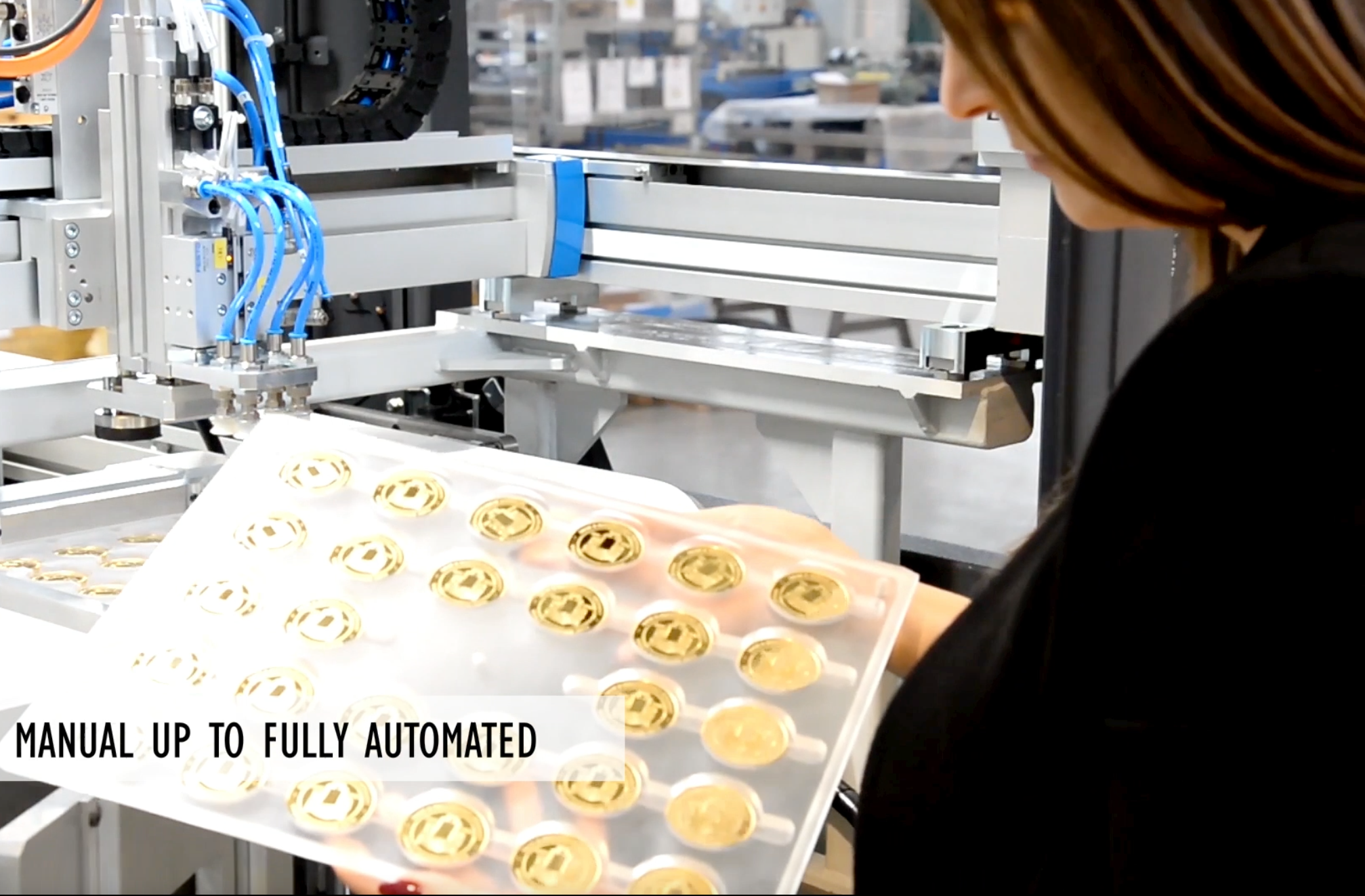

Efficient manufacturing of high-quality products saw the Industrial Revolution shape our understanding of progress.

Setting Standards

Torbjørn Hansen (General Manager, Kongsberg Mechatronics AS) commented on this benefit during the Q&A session at the 17th Technical Forum 2021 by saying, “… This is what I want from a machine supplier. Right timing in this corona times.”

SETTING STANDARDS. That’s our mission.

Virtual- & Augmented Reality

The World Money Fair 2020 saw Sack & Kiesselbach present the successful TMA 350 press VIRTUALLY for the first time, and the responsive was very positive. This important step toward “Industry 4.0” extends well beyond mere Computer Aided Design (CAD) work. Virtual reality (VR) and augmented reality (AR) are decisively optimizing production and maintenance processes. Every processing step is visible by the customer and the technician on the machine itself, thereby aiding ad-hoc decisions and speeding up manufacturing and/or problem-solving, including remotely.

Assisted Reality

While VR allows customers to see the machines virtually, and AR uses QR codes to perform actions such as changing tools directly on smart devices, ASSISTED REALITY provides the customer’s technician with live support from Sack & Kiesselbach’s support team, no matter where they are in the world. And smart glasses mean the technician also has both hands free. The support team watches every move by the technician, and can instruct him or her in real time, regardless of where in the world the machine is.

more technology topics

New dimensions of minting

The Mint of Poland produces a coin in the shape of a sphere. An upstroke hobbing press by Sack & Kiesselbach is being used for this.