Compact design and greater flexibility

The downstroking press is a reliable partner for customers who offer a wide product range.

Reliable metal working in the highest press force range

Compact design with high flexibility.

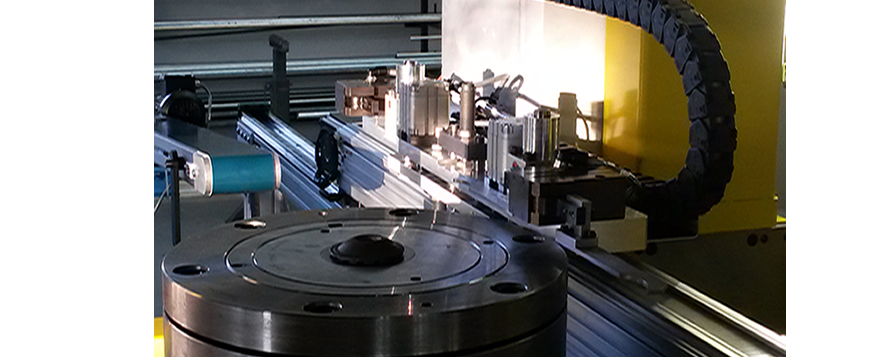

Powerful downstroking press in many equipment variants 3,150-25,000 kN.

The downstroking press (OKP) is a reliable partner for customers offering a wide range of products.

Productivity

- Variable stroke

- Variable pressing force and pressing speed in every stroke range

- Multiple pressing

- Adjustable dwell time

- Many different automation solutions

- Precision tools

Ergonomy

- Lower sound emission due to the sound insulating cabinet

- Very short set up and tool changing times

Technology

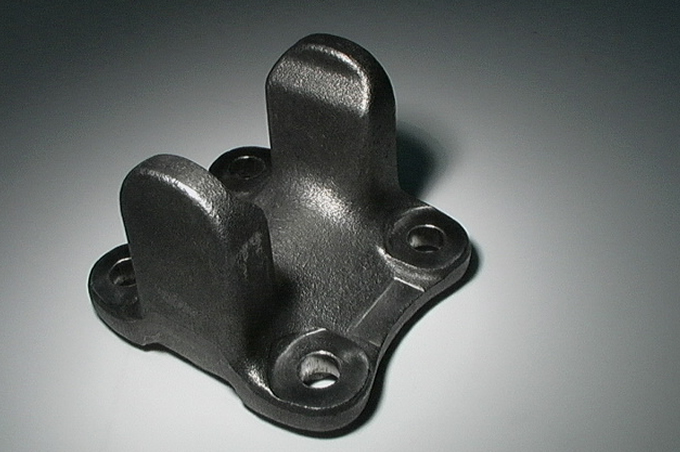

- Compact, inherently stable, one-piece cast press stands with down stroking drive, designed for centric loading

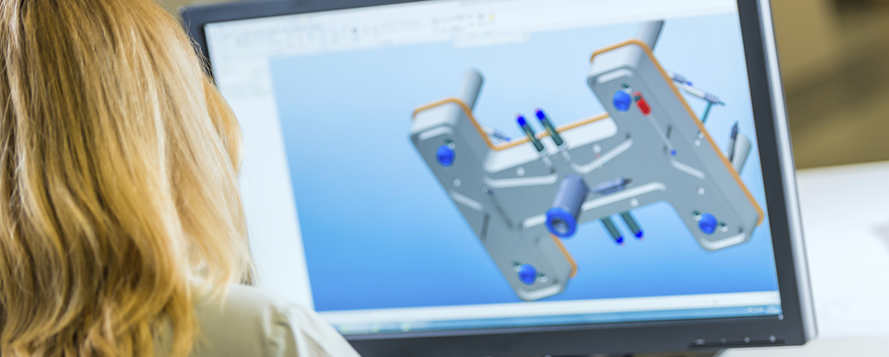

- Menu-guided press operation using the Siemens® S7 control unit

- Press designed in accordance with the EU Machinery Regulation

- Energy-saving servo drive as an optional extra

Whether manual feed or automated, the downstroking press impresses with its flexibility.

The press can be configured individually depending on customer requirements and so, for example, the customer can freely select the type of drive to be used, either a servo motor or a conventional one.

With a maximum pressing force of 25,000 kN, the downstroking press is eminently suitable for working very large top quality pressed parts.

See also

Our presses are as unique as our customers

No two orders are the same. Every customer poses new challenges for us. We develop integrated, turnkey system solutions. Tailor-made for our customers’ individual requirements.

Industriepressen von Sack & Kiesselbach finden laufend neue Einsatzgebiete

Our oil hydraulic press systems are not only found in the forging industry. The automotive, medicine and pharmaceutical industries also value our reliability.