Continuity in tool construction

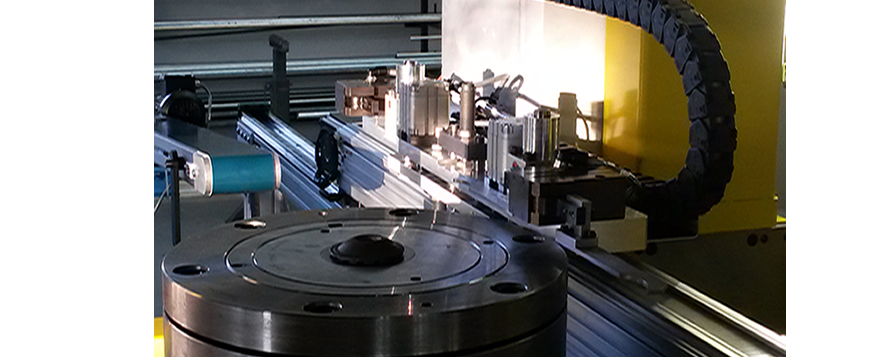

The hobbing press (EP) is the cost-effective companion for the production of punches and dies.

Continuity in tool construction

Hobbing in highest precision

Upstroking hobbing press and tool system from one place 6,300–25,000 kN

The hobbing press (EP) is the cost-effective companion for the production of punches and dies.

Productivity

- Infinitely adjustable path and pressing force controls

- Infinitely adjustable dwell time from 0.1 to 2 seconds.

- Infinitely adjustable hobbing speed

- Table ejector

- Function – Multiple pressing in closed tool

- Hobbing tolerance: +/- 0.02mm (length and eccentricity)

- Quick tool change systems (optional)

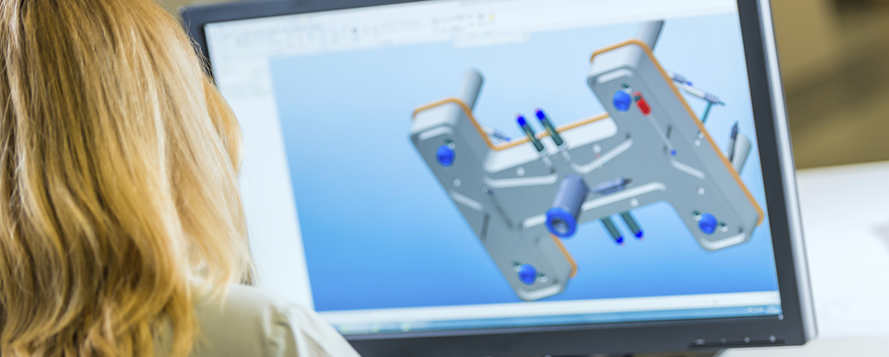

- Precision hobbing tool

Technology

- Compact, inherently stable, one part cast press stands

- Lower ram drive for centric loading

- Menu-guided press operation using the Siemens® S7 control unit

- Press designed in accordance with the EU Machinery Regulation

Together with a precision hobbing tool, the EP impresses customers all over the world.

When manufacturing production punches, maximum precision is required in terms of eccentricity and punch length. Here we offer our customers the whole package for tool constructuion.

See also

Our presses are as unique as our customers

No two orders are the same. Every customer poses new challenges for us.

We develop integrated, turnkey system solutions. Tailor-made for our customers’ individual requirements.

Our industrial presses are constantly finding new applications

Our oil hydraulic press systems are not only found in the forging industry. The automotive, medicine and pharmaceutical industries also value our reliability.