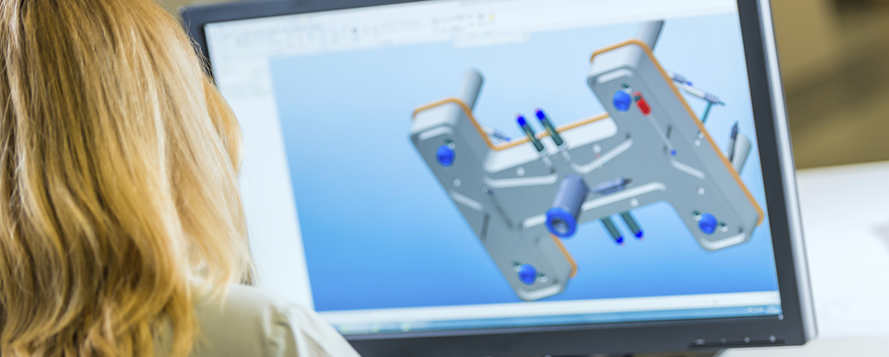

Highest minting quality even with the most difficult images

Compact table medal press with standard direct servo drive 2,500 + 3,500 kN

Sensitive control systems for best results

The table medal press (TMP) sets the standards for embossing coins and medals.

Ergonomy

- Very short set up and tool changing times

- Can be operated sitting down

- Lower sound emission

Productivity

- Variable stroke

- Variable pressing force and press speed in every stroke range

- Multiple pressing

- Adjustable dwell time

- Hologram function

- Lifting

- Many different automation solutions, such as embossing bi-metal

- Precision medal tools

Technology

- Compact, inherently stable, one-piece cast press stands with upper ram drive, designed for centric loading

- Assembled on a common base plate

- Energy-saving servo drive

- Menu-driven press operation using the Siemens® S7 control unit

- Press designed in accordance with the EU Machinery Regulation

The controlled, energy-saving servo drive enables all parameters in the embossing process to be set to deal with the part to be embossed.

There is a large number of options available, from the simplest manual feed solution through partial automation up to automatic production machines.

All feed units are designed in such a way as to ensure that the tool area is extremely accessible.

Tools can be changed in a very short time.

With the TMP we supply the most varied customised equipment models for coin manufacturers all over the world.

The press’s small footprint is impressive. All units are fitted compactly onto a base plate. Presses can be assembled and commissioned in the shortest possible time.

See also

Our presses are as unique as our customers

No two orders are the same. Every customer poses new challenges for us.

We develop integrated, turnkey system solutions. Tailor-made for our customers’ individual requirements.

Our industrial presses are constantly finding new applications

Our oil hydraulic press systems are not only found in the forging industry. The automotive, medicine and pharmaceutical industries also value our reliability.